Installation

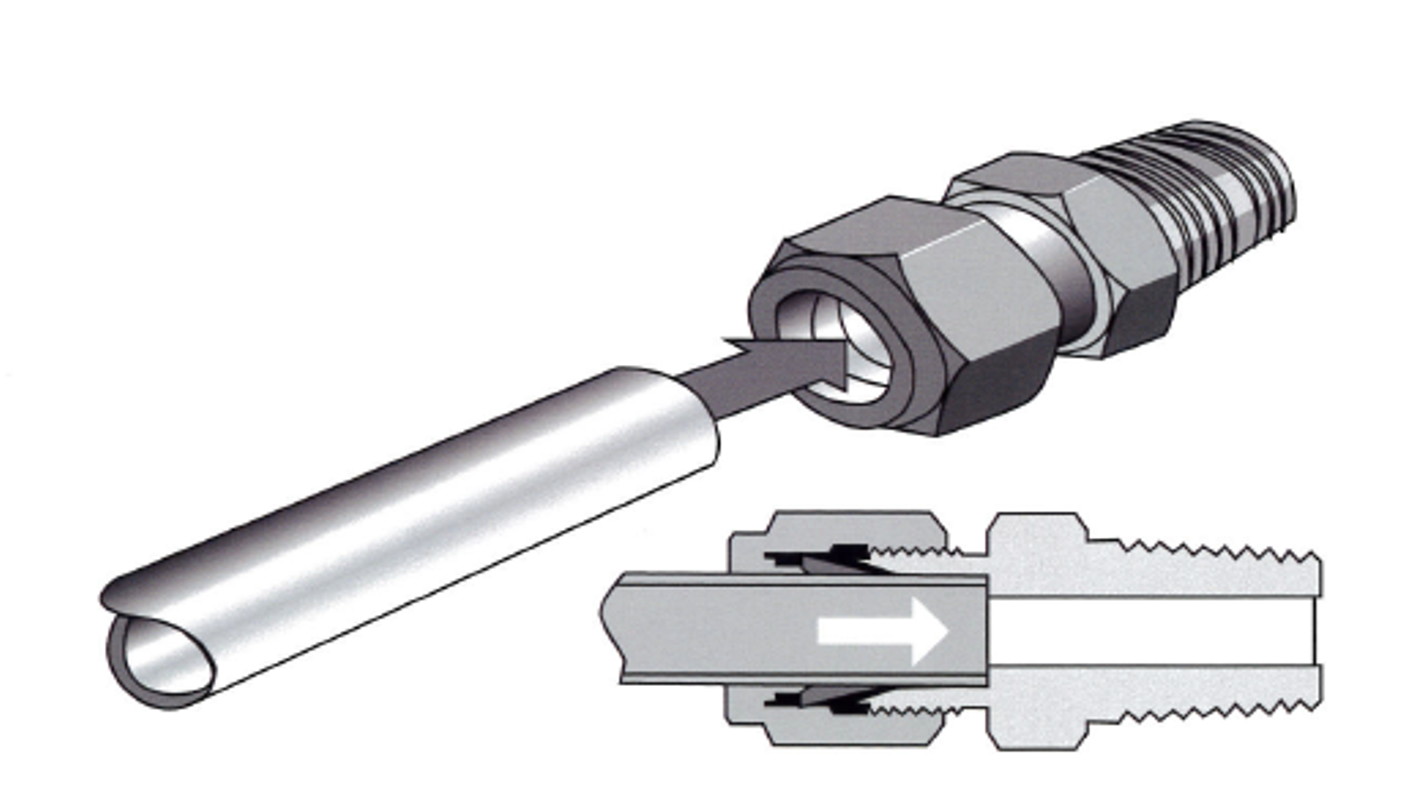

The tube must always be fully inserted into the fitting and “bottomed out” against the shoulder (failure to achieve these conditions could result in leakage). The nut is then rotated until it is finger tight.

When dealing with “severe service” lines i.e. high pressure and or high safety applications some manufactures recommend the nut to be tightened beyond finger tight; to a state when the tube no longer turns in the fitting. This practice is not recommended by PARKER

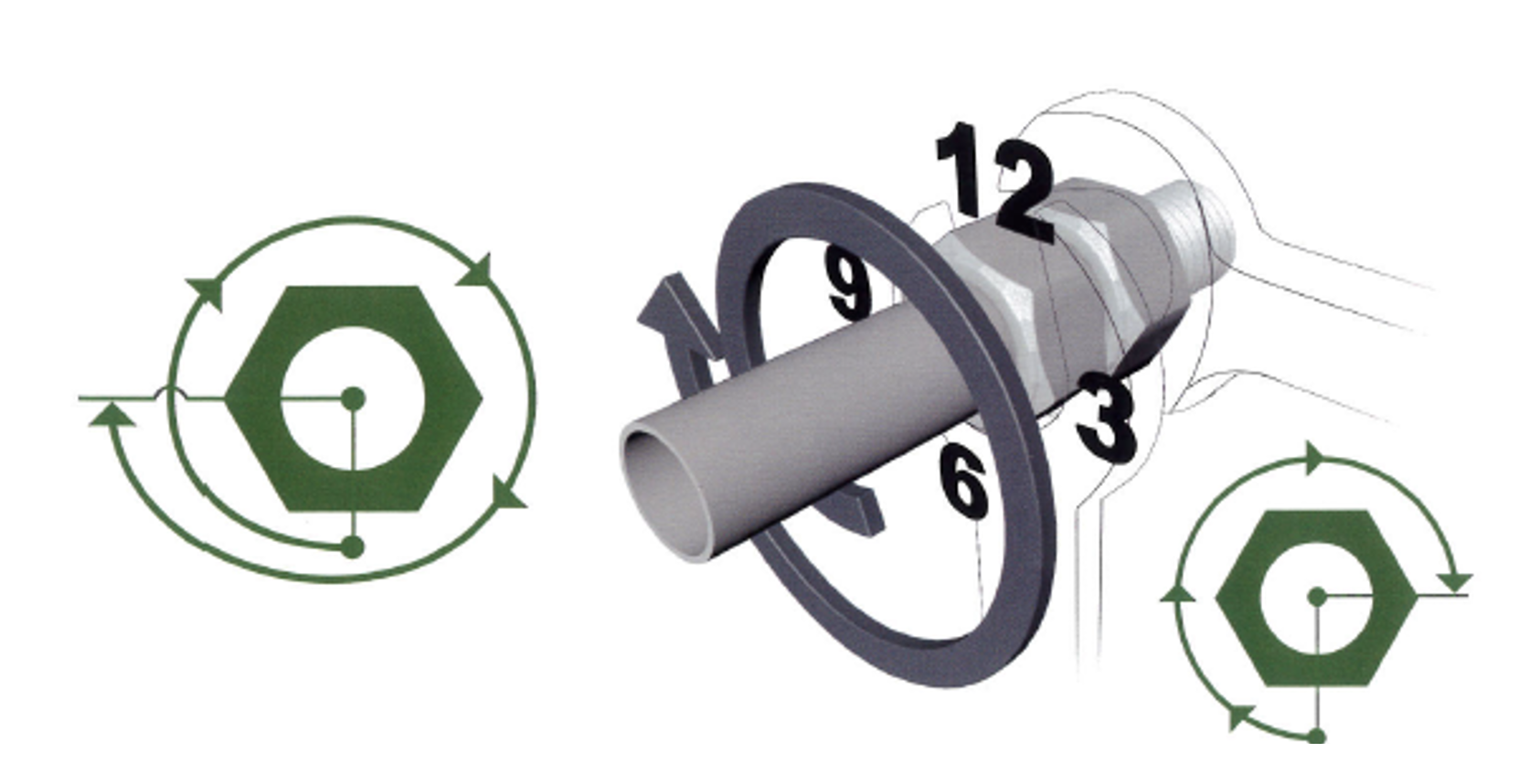

Imagine a clock face around the nut, mark the nut at the 6 o’clock position.

Holding the fitting body in a secure position, tighten the nut 1 & ¼ turns, the line marked on the nut should now be at the 9 o’clock position.

For fitting sizes of less than 6mm or ¼” the nut only needs to be tightened ¾ turns finishing at 3 o’clock position.